On August 8, SMART Transportation Division submitted comments to the Pipeline and Hazardous Materials Safety Administration (PHMSA) regarding the proposal of transporting liquid natural gas (LNG) by rail.

In our comments, National Legislative Director John Risch recognizes the potential safety hazards associated with the transportation of LNG by rail, but also points out that the Federal Railroad Administration (FRA) has established safety protocols and procedures to transport it safely.

“Recognizing the safety hazards involved and the work FRA safety experts have already done on this issue, we support the transport of LNG by rail provided the conditions imposed by FRA in their November 2, 2015, letter of authority to the Alaska Railroad, and the restrictions contained in the March 3, 2016, letter to the Florida East Coast Railway are imposed,” Risch wrote.

Click here to read our full comments as well as the FRA letters mentioned above.

Tag: safety

The U.S. House of Representatives on Monday, June 24, passed an amendment that would block President Donald Trump’s Executive Order in April to the Department of Transportation to fast-track the allowance of liquid natural gas (LNG) to be transported by rail.

“In its never-ending quest to put profit ahead of people, the Trump administration is now trying to bypass long-standing requirements for transportation of LNG by putting it into 100-car trains that roll through densely-populated areas at upwards of 50 miles per hour,” said U.S. Rep. Peter DeFazio (D – Ore.), chair of the House Committee on Transportation and Infrastructure, who introduced the amendment. “This plan is beyond absurd. Should even one tank car get punctured, the results could be devastating. My amendment blocks this brazen attempt by the administration. I urge the Senate to follow suit and stop a massive catastrophe before it’s too late.”

The Pipeline and Hazardous Materials Safety Administration (PHMSA) moved ahead earlier this month with a plan to authorize six trains, of 100 or more rail tank cars, to move LNG for export through densely populated areas. DeFazio’s amendment would block this special permit as well, which currently is open for comment until July 8.

Read more on this story at Freightwaves.com.

Read an earlier story about the executive order.

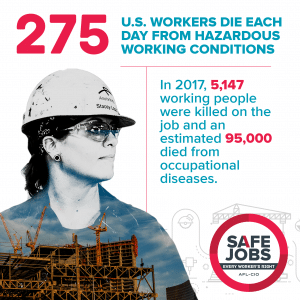

According to the AFL-CIO, “Workplace violence is the third-leading cause of death on the job, resulting in more than 29,000 serious, lost-time injuries for workers each year.”

According to the report, in 2017, 5,147 workers lost their lives on the job as a result of traumatic injuries and each day, an average of 14 workers die due to on-the-job injuries. An estimated, 95,000 people die each year from occupational diseases.

The report also states that nearly 3.5 million workers in the public sector had work-related injuries and illnesses, with an additional 2.8 million injuries reported in the private sector. Due to limitations to the current injury reporting system and widespread under-reporting of injuries in the workplace, the AFL-CIO estimates that the true numbers are two to three times greater than these at about 7.0 million to 10.5 million work-related injuries and illnesses per year.

Click here to read the rest of the report from the AFL-CIO.

Of the $345 million recently allocated, Amtrak received $10 million to “protect critical surface transportation infrastructure and the public from acts of terrorism and to increase the resilience of the Amtrak rail system.”

The DHS allocated $88 million to the Transit Security Grant Program (TSGP). “The TSGP provides money to owners and operators of transit systems to protect critical surface transportation and the traveling public from acts of terrorism and to increase the resilience of transit infrastructure.”

Some of the recipients of the TSGP include Dallas Area Rapid Transit ($542,905), SEPTA ($3.6 million), WMATA ($5.4 million), LACMTA ($6.2 million) and many others.

The Intercity Bus Security Grant Program (IBSGP) was allocated $2 million to “assist operators of fixed-route intercity and charter bus services in high threat urban areas to protect bus systems and the traveling public from acts of terrorism, major disasters and other emergencies.”

Click here for a press release from DHS detailing which agencies are awarded funds.

by The National Healthy Sleep Awareness Project

Sleep deprivation impacts workplace safety, productivity and individual health

(DARIEN, Ill.) March 2018 – Getting insufficient sleep and working while fatigued have become commonplace in the modern 24/7 workforce, with more than 37 percent of workers sleep-deprived.[i] Over-worked and over-tired employees experience cognitive declines and present employers with heightened safety risks and increased economic costs. The National Healthy Sleep Awareness Project – including partners the American Academy of Sleep Medicine (AASM), the Centers for Disease Control and Prevention (CDC), the Sleep Research Society (SRS) and the National Safety Council (NSC) – is launching the “Sleep Works for You” campaign, encouraging employers to help workers avoid fatigue and develop healthy sleep habits for long-term success and well-being.

“Working long hours and sleeping less than the recommended seven or more hours has become a badge of honor in many industries, despite evidence that proves a lack of sleep hurts productivity, safety and overall health,” said AASM President Dr. Ilene Rosen. “It is essential for employers to promote health and safety by creating a workplace culture that values the importance of sleep.”

The National Healthy Sleep Awareness Project encourages employers to promote sleep health in the workplace with three steps:

- Learn about sleepiness in the workplace, its costs, its causes and how fatigue can lead to a higher rate of safety incidents

- Educate employees on fatigue, sleep health and sleep disorders, as well as strategies to improve alertness on the job, as part of a comprehensive employee wellness program

- Investigate the causes of fatigue in the workplace and implement fatigue risk management as part of a safety management system

“Nearly 70 million Americans suffer from a sleep problem, and nearly 60 percent of them have a chronic disease that can harm their overall health,” said Janet B. Croft, PhD, senior chronic disease epidemiologist in CDC’s Division of Population Health. “Lack of sleep and sleep disorders, including stops in breathing during sleep (sleep apnea), excessive daytime sleepiness (narcolepsy), restless legs syndrome, and insomnia, are increasingly recognized as linked to chronic disease, including obesity, high blood pressure, and cancer.”

The Cost of Fatigue

According to the NSC, fatigued workers cost employers about $1,200 to $3,100 per employee in declining job performance each year, while sleepy workers are estimated to cost employers $136 billion a year in health-related lost productivity.

To help employers gauge how much fatigue may be adding to annual expenditures, NSC and Brigham and Women’s Hospital created an online Fatigue Cost Calculator.

“Sleepless nights hurt everyone,” said NSC President and CEO Deborah A.P Hersman. “Many of us have been conditioned to just power through our fatigue, but worker health and safety on the job are compromised when we don’t get the sleep we need. Doing nothing to address fatigue costs employers a lot more than they think.”

Impact of Sleepiness on Safety

Sleepiness causes decreased performance capacity, and tired workers become slower, more error prone and less productive. Research shows that fatigue impairs employees’ ability to function properly and puts them at a greater risk of a safety incident.[ii] In fact, about 13 percent of work injuries are attributable to sleep deprivation.[iii]

Sleepiness also impacts safety for those who drive as part of their job or commute to and from work. The National Transportation Safety Board (NTSB) estimates that fatigue has been a contributing factor in 20 percent of its investigations over the last two decades. That’s why the NTSB included “reduce fatigue-related accidents” on its 2017 – 2018 Most Wanted List of transportation safety improvements.

In February, the AAA Foundation for Traffic Safety released a research brief estimating that drowsy driving is involved in up to 9.5 percent of all motor vehicle crashes. Projections from the AAA Foundation indicate that drowsy driving causes an average of 328,000 motor vehicle accidents in the U.S. each year, including 6,400 fatal crashes.

Maximizing Health of Shift Workers

The effects of sleepiness are exacerbated and pose a constant struggle for workers who work night shifts or rotating shifts, and for those who work long hours or have an early morning start time. U.S. Bureau of Labor statistics show about 15 percent of full-time employees in the U.S. perform shift work, many of whom suffer from chronic sleep loss caused by a disruption in the body’s circadian rhythm. Chronic sleep deprivation is associated with an increased risk of depression, obesity, cardiovascular disease and other illnesses that negatively impact a worker’s well-being and long-term health.

There are significant differences in the rate of insufficient sleep among occupations. A recent CDC analysis found that the jobs with the highest rates of short sleep duration were communications equipment operators (58.2%), other transportation workers (54.0%) and rail transportation workers (52.7%).

Night shift workers and those driving during nighttime hours are most at risk for chronic sleep loss. The NSC found that 59 percent of night shift workers reported short sleep duration compared to 45 percent of day workers, while the risk of safety incidents was 30 percent higher during night shifts compared to morning shifts.

Employers with personnel in safety-sensitive positions are urged to implement a fatigue risk management system. The National Institute for Occupational Safety and Health (NIOSH) provides educational resources on sleep, shiftwork, and fatigue for employees and managers involved in aviation, emergency response, healthcare, railroads and trucking.

Employers can help shift workers fight fatigue by implementing the following strategies:

- Avoid assigning permanent night-shift schedules

- Assign regular, predictable schedules

- Avoid long shift lengths

- Give employees a voice in their schedules

- Rotate shifts forward when regularly changing shifts

- Provide frequent breaks within shifts

For more information on how to keep employees safe from risks and costs of fatigue, please visit www.projecthealthysleep.org.

###

About the National Healthy Sleep Awareness Project

The National Healthy Sleep Awareness Project was initiated in 2013 and is funded by the Centers for Disease Control and Prevention through a cooperative agreement with the American Academy of Sleep Medicine. The project involves collaboration with the Sleep Research Society and other partners to address the sleep health focus area of Healthy People 2020, which provides science-based, 10-year national objectives for improving the health of all Americans. The sleep health objectives are to increase the medical evaluation of people with symptoms of obstructive sleep apnea, reduce vehicular crashes due to drowsy driving and ensure more Americans get sufficient sleep. For more information, visit www.projecthealthysleep.org.

[i] Yong LC, Li J, Calvert GM. “Sleep-related problems in the US working population: prevalence and association with shiftwork status.” Occup Environ Med Published Online First: 08 September 2016. doi: 10.1136/oemed-2016-103638

[ii] Lombardi, D. A., Folkard, S., Willetts, J. L., & Smith, G. S. (2010). Daily sleep, weekly working hours, and risk of work-related injury: US National Health Interview Survey (2004–2008). Chronobiology international, 27(5), 1013-1030

[iii] Uehli, K. “Sleep problems and work injuries: a systematic review and meta-analysis.” Sleep Med Rev. 2014 Feb;18(1):61-73. doi: 10.1016/j.smrv.2013.01.004. Epub 2013 May 21.

The Federal Railroad Administration (FRA) received one urgent safety recommendation based on NTSB findings in the agency’s investigation of the Feb. 4, 2018, collision of an Amtrak train and a CSX train near Cayce, S.C. The conductor and engineer of the Amtrak train died as a result of the collision. The NTSB issued two urgent safety recommendations to the Metropolitan Transportation Authority (MTA) based on findings from its investigation of the June 10, 2017, Long Island Rail Road (LIRR) accident in which a roadway worker died near Queens Village, N.Y.

In the investigation of the train collision in Cayce, South Carolina, investigators found that on the day before the accident, CSX personnel suspended the traffic control signal system to install updated traffic control system components for the implementation of positive train control (PTC). The lack of signals required dispatchers to use track warrants to move trains through the work territory.

In this accident, and in a similar March 14, 2016, accident in Granger, Wyo., safe movement of the trains, through the signal suspension, depended upon proper switch alignment. That switch alignment relied on error-free manual work, which was not safeguarded by either technology or supervision, creating a single point of failure.

The NTSB concludes additional measures are needed to ensure safe operations during signal suspension and so issued an urgent safety recommendation to the FRA seeking an emergency order directing restricted speed for trains or locomotives passing through signal suspensions when a switch has been reported relined for a main track.

“The installation of the life-saving positive train control technology on the CSX tracks is not the cause of the Cayce, S.C. train collision,” said NTSB Chairman Robert Sumwalt.

“While the collision remains under investigation, we know that signal suspensions are an unusual operating condition, used for signal maintenance, repair and installation, that have the potential to increase the risk of train collisions. That risk was not mitigated in the Cayce collision. Our recommendation, if implemented, works to mitigate that increased risk.” said Sumwalt.

During the investigation of the LIRR accident, the NTSB identified an improper practice by LIRR roadway workers who were working on or near the tracks. LIRR employees were using “train approach warning” as their method of on-track safety, but they did not clear the track, as required, when trains approached and their “predetermined place of safety” did not comply with LIRR rules and procedures.

The NTSB is concerned LIRR management is overlooking and therefore normalizing noncompliance with safety rules and regulations for proper clearing of tracks while using “train approach warning” for worker protection. The two urgent safety recommendations to the MTA call for MTA to audit LIRR’s use of “train approach warning” for worker protection, and, to implement corrective action for deficiencies found through the audit.

The full safety recommendation reports for these urgent safety recommendations are available online at https://goo.gl/z87Dpz and https://goo.gl/LVVef3.

“Operation Lifesaver is working to change people’s behavior around railroad tracks and crossings with our educational materials and tips for people of all ages,” said OLI Interim President Wende Corcoran.

“Every year, approximately 900 trespassers and over 1,000 motorists are involved in incidents along train tracks or at grade crossings,” she continued. “Reaching school-aged students with free presentations by our volunteers that are interesting, fun and that convey lifesaving information is an important part of our multi-faceted approach to reducing those numbers.”

The number of trespassers killed or injured while trespassing on railroad tracks and property rose in 2015 and 2016, according to Federal Railroad Administration statistics. Corcoran noted that the new resources have been specifically designed to deliver age-appropriate trespass prevention messages.

The new Operation Lifesaver, Inc. materials include:

- The Trains & Tracks presentation, for use with children in grades K-2 or between the ages of 5-8, introduces young children to basic safety messages and train attributes, emphasizing the importance of using caution around trains and tracks. The information is presented as a story, “Train and the Whateveritwas,” which incorporates key safety messages in an entertaining and engaging format.

- The Train Safety Savvy presentation, for use with children in grades 3-5 or between the ages of 8-11, covers general safety messages, signs and signals, and trespass prevention messages using information and interactive games sequences to keep the attention of this age group.

- The Main Line Middle School presentation, which uses emoji-like characters in a colorful, yearbook-style story line to appeal to smart phone-savvy students in grades 6-8 or ages 11-13, covers general safety messages, signs and signals, and trespass prevention messages.

Corcoran said that the three new educational tools are available for viewing on the OL for Kids section of the Operation Lifesaver, Inc. website. She noted that Operation Lifesaver Authorized Volunteers (OLAVs) may access and download all of these new materials in the Education Materials section of the website, as they do with all OLI presentation materials.

“We are excited to share these new educational materials with students, educators and schools across the U.S.,” said Corcoran.

About Operation Lifesaver – Operation Lifesaver is a nonprofit public safety education and awareness organization dedicated to reducing collisions, fatalities and injuries at highway-rail crossings and preventing trespassing on or near railroad tracks. A national network of trained volunteers provides free presentations on rail safety and a public awareness campaign, “See Tracks? Think Train!” equips the public with tips and statistics to encourage safe behavior near the tracks. Learn more at http://www.oli.org.

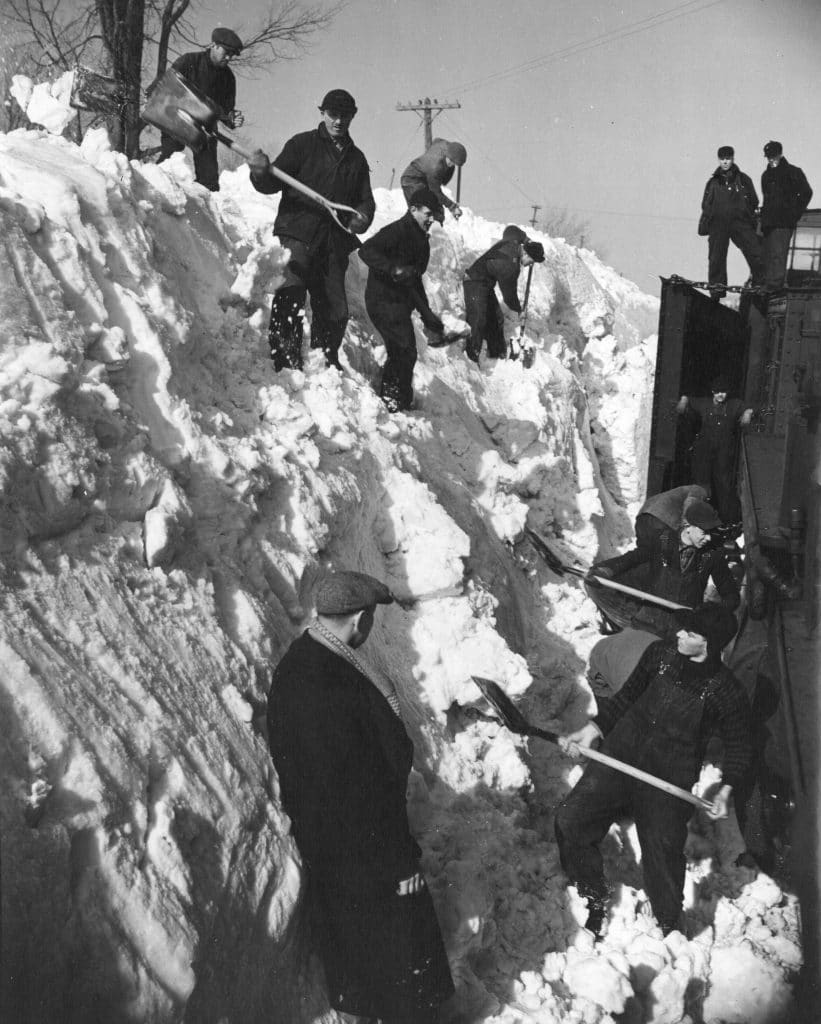

OSHA and National Oceanic and Atmospheric Administration (NOAA) are working together on a public education effort aimed at improving the way people prepare for and respond to severe weather. Here is some information provided by OSHA to help businesses and their workers prepare for winter weather, and to provide information about hazards that workers may face during and after winter storms.

Winter preparedness

Outdoor work requires proper preparation, especially in severe winter weather conditions. Although OSHA does not have a specific standard that covers working in cold environments, employers have a responsibility to provide workers with employment and a place of employment which are free from recognized hazards, including winter weather related hazards, which are causing or are likely to cause death or serious physical harm to them (Section 5(a)(1) of the Occupational Safety and Health Act of 1970). Employers should, therefore, train workers on the hazards of the job and safety measures to use, such as engineering controls and safe work practices, that will protect workers’ safety and health.

Employers should train workers

At a minimum, employers should train workers on:

- Cold Stress:

- How to recognize the symptoms of cold stress, prevent cold stress injuries and illnesses

- The importance of self-monitoring and monitoring coworkers for symptoms

- First aid and how to call for additional medical assistance in an emergency

- How to select proper clothing for cold, wet and windy conditions

- Other winter weather related hazards that workers may be exposed to, for example, slippery roads and surfaces, windy conditions and downed power lines

- How to recognize these hazards

- How workers will be protected: engineering controls, safe work practices and proper selection of equipment, including personal protective equipment

Employers should implement safe work practices

Safe work practices that employers can implement to protect workers from injuries, illnesses and fatalities include:

- Providing workers with the proper tools and equipment to do their jobs

- Developing work plans that identify potential hazards and the safety measures that will be used to protect workers

- Scheduling maintenance and repair jobs for warmer months

- Scheduling jobs that expose workers to the cold weather in the warmer part of the day

- Avoiding exposure to extremely cold temperatures when possible

- Limiting the amount of time spent outdoors on extremely cold days

- Using relief workers to assign extra workers for long, demanding jobs

- Providing warm areas for use during break periods

- Providing warm liquids (no alcohol) to workers

- Monitoring workers who are at risk of cold stress

- Monitoring the weather conditions during a winter storm, having a reliable means of communicating with workers and being able to stop work or evacuate when necessary

- Acclimatizing new workers and those returning after time away from work by gradually increasing their workload, and allowing more frequent breaks in warm areas, as they build up a tolerance for working in the cold environment

- Having a means of communicating with workers, especially in remote areas

- Knowing how the community warns the public about severe weather: outdoor sirens, radio and television

- The National Oceanic and Atmospheric Administration (NOAA) provides multiple ways to stay informed about winter storms. If you are notified of a winter storm watch, advisory or warning, follow instructions from your local authorities: NOAA Weather Radio

Employers should consider protective clothing that provides warmth

Employers must provide personal protective equipment (PPE), for example, fall protection, when required by OSHA standards to protect workers’ safety and health. However, in limited cases specified in the standard (29 CFR 1910.132), there are exceptions to the requirement for employers to provide PPE to workers. For instance, there is no OSHA requirement for employers to provide workers with ordinary clothing, skin creams or other items, used solely for protection from weather, such as winter coats, jackets, gloves, parkas, rubber boots, hats, raincoats, ordinary sunglasses and sunscreen (29 CFR 1910.132(h)(4)). Regardless of this, many employers provide their workers with winter weather gear such as winter coats/jackets and gloves.

Learn more about PPE requirements: Personal Protective Equipment (OSHA Safety and Health Topics Page).

Wind Chill temperature

National Weather Service (NWS) Wind Chill Calculator: With this tool, one may input the air temperature and wind speed, and it will calculate the wind chill temperature.

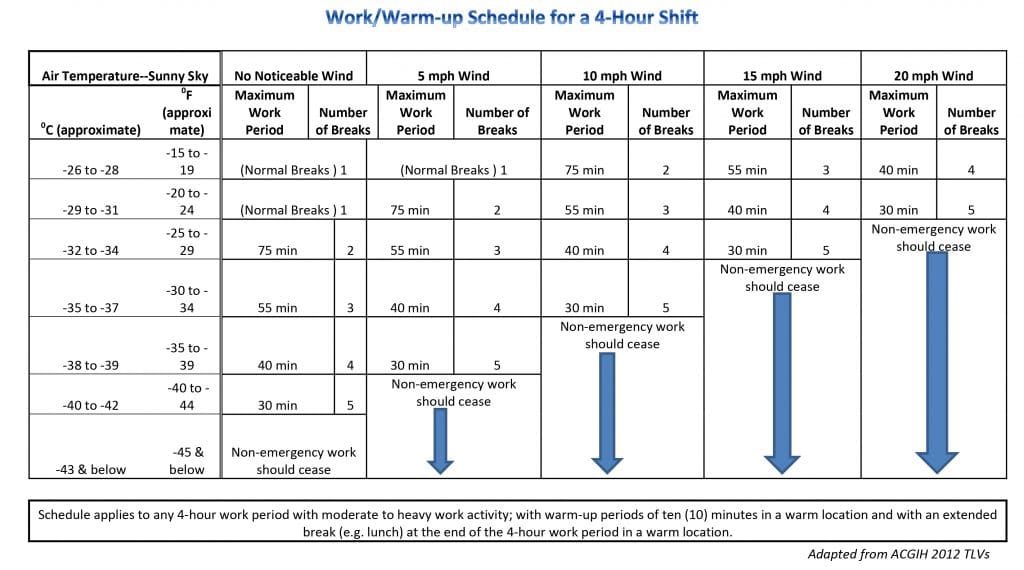

The American Conference of Governmental Industrial Hygienists (ACGIH) developed the following Work/Warm-up Schedule for a 4-hour shift takes both air temperature and wind speed into account, to provide recommendations on scheduling work breaks and ceasing non-emergency work.

Cold Stress

Cold Stress can be prevented

The National Oceanic and Atmospheric Administration (NOAA) Weather Radio is a nationwide network of radio stations broadcasting continuous weather information from the nearest NWS office. It will give information when wind chill conditions reach critical thresholds. A Wind Chill Warning is issued when wind chill temperatures are life threatening. A Wind Chill Advisory is issued when wind chill temperatures are potentially hazardous.

Who is affected by environmental cold?

Environmental cold can affect any worker exposed to cold air temperatures and puts workers at risk of cold stress. As wind speed increases, it causes the cold air temperature to feel even colder, increasing the risk of cold stress to exposed workers, especially those working outdoors, such as recreational workers, snow cleanup crews, construction workers, police officers and firefighters. Other workers who may be affected by exposure to environmental cold conditions include those in transit, baggage handlers, water transportation, landscaping services and support activities for oil and gas operations.

Risk factors for cold stress include:

- Wetness/dampness, dressing improperly and exhaustion

- Predisposing health conditions such as hypertension, hypothyroidism and diabetes

- Poor physical conditioning

What is cold stress?

What constitutes cold stress and its effects can vary across different areas of the country. In regions that are not used to winter weather, near freezing temperatures are considered factors for “cold stress.” Increased wind speed also causes heat to leave the body more rapidly (wind chill effect). Wetness or dampness, even from body sweat, also facilitates heat loss from the body. Cold stress occurs by driving down the skin temperature, and eventually the internal body temperature. When the body is unable to warm itself, serious cold-related illnesses and injuries may occur, and permanent tissue damage and death may result. Types of cold stress include: trench foot, frostbite and hypothermia.

For more information, see OSHA’s Cold Stress Safety and Health Guide.

How can cold stress be prevented?

Although OSHA does not have a specific standard that covers working in cold environments, under the Occupational Safety and Health Act (OSH Act) of 1970, employers have a duty to protect workers from recognized hazards, including cold stress hazards, that are causing or likely to cause death or serious physical harm in the workplace.

- Employers should train workers. Training should include:

- How to recognize the environmental and workplace conditions that can lead to cold stress.

- The symptoms of cold stress, how to prevent cold stress and what to do to help those who are affected.

- How to select proper clothing for cold, wet and windy conditions.

- Employers should:

- Monitor workers physical condition.

- Schedule frequent short breaks in warm, dry areas to allow the body to warm up.

- Schedule work during the warmest part of the day.

- Use the buddy system (work in pairs).

- Provide warm, sweet beverages. Avoid drinks with alcohol.

- Provide engineering controls such as radiant heaters.

Types of Cold Stress

Immersion/Trench Foot

Trench foot is a non-freezing injury of the feet caused by prolonged exposure to wet and cold conditions. It can occur in temperatures as high as 60°F if feet are constantly wet. Injury occurs because wet feet lose heat 25 times faster than dry feet.

What are they symptoms of trench foot?

Reddening skin, tingling, pain, swelling, leg cramps, numbness and blisters.

First Aid

- Call 911 immediately in an emergency; otherwise seek medical assistance as soon as possible.

- Remove wet shoes/boots and wet socks.

- Dry the feet and avoid working on them.

- Keep affected feet elevated and avoid walking. Get medical attention.

Frostbite

Frostbite is caused by the freezing of the skin and tissues. Frostbite can cause permanent damage to the body, and in severe cases can lead to amputation. The risk of frostbite is increased in people with reduced blood circulation and among people who are not dressed properly for extremely cold temperatures.

What are the symptoms of frostbite?

Reddened skin develops gray/white patches in the fingers, toes, nose or ear lobes; tingling, aching, a loss of feeling, firm/hard blisters may occur in the affected areas.

First Aid

- Follow the recommendations described below for hypothermia.

- Protect the frostbitten area, e.g., by wrapping loosely in a dry cloth and protect the area from contact until medical help arrives.

- DO NOT rub the affected area, because rubbing causes damage to the skin and tissue.

- Do not apply snow or water. Do not break blisters.

- DO NOT try to re-warm the frostbitten area before getting medical help, for example, do not use heating pads or place in warm water. If a frostbitten area is rewarmed and gets frozen again, more tissue damage will occur. It is safer for the frostbitten area to be rewarmed by medical professionals.

- Give warm sweetened drinks if alert (no alcohol).

Hypothermia

Hypothermia occurs when the normal body temperature (98.6°F) drops to less than 95°F. Exposure to cold temperatures causes the body to lose heat faster than it can be produced. Prolonged exposure to cold will eventually use up the body’s stored energy. The result is hypothermia, or abnormally low body temperature. Hypothermia is most likely at very cold temperatures, but it can occur even at cool temperatures (above 40°F) if a person becomes chilled from rain, sweat or immersion in cold water.

What are the symptoms of hypothermia?

An important mild symptom of hypothermia is uncontrollable shivering, which should not be ignored. Although shivering indicates that the body is losing heat, it also helps the body to rewarm itself. Moderate to severe symptoms of hypothermia are loss of coordination, confusion, slurred speech, heart rate/breathing slow, unconsciousness and possibly death. Body temperature that is too low affects the brain, making the victim unable to think clearly or move well. This makes hypothermia particularly dangerous because a person may not know what is happening and won’t be able to do anything about it.

First Aid

- Call 911 immediately in an emergency:

- Move the worker to a warm, dry area.

- Remove any wet clothing and replace with dry clothing. Wrap the entire body (including the head and neck) in layers of blankets; and with a vapor barrier (e.g. tarp, garbage bag) Do not cover the face.

- If medical help is more than 30 minutes away:

- Give warm sweetened drinks if alert (no alcohol), to help increase the body temperature. Never try to give a drink to an unconscious person.

- Place warm bottles or hot packs in armpits, sides of chest and groin. Call 911 for additional rewarming instructions.

Basic Life Support (when necessary)

Co-workers trained in cardiopulmonary resuscitation (CPR) may help a person suffering from hypothermia that has no pulse or is not breathing:

- Call 911 for emergency medical assistance immediately.

- Treat the worker as per instructions for hypothermia, but be very careful and do not try to give an unconscious person fluids.

- Check him/her for signs of breathing and for a pulse. Check for 60 seconds.

- If after 60 seconds the affected worker is not breathing and does not have a pulse, trained workers may start rescue breaths for 3 minutes.

- Recheck for breathing and pulse, check for 60 seconds.

- If the worker is still not breathing and has no pulse, continue rescue breathing.

- Only start chest compressions per the direction of the 911 operator or emergency medical services*

- Reassess patient’s physical status periodically.

*Chest compression are recommended only if the patient will not receive medical care within three hours.

Winter driving

Although employers cannot control roadway conditions, they can promote safe driving

Employers should set and enforce driver safety policies. Employers should also implement an effective maintenance program for all vehicles and mechanized equipment that workers are required to operate. Crashes can be avoided. Learn more at: Motor Vehicle Safety (OSHA Safety and Health Topic’s Page).

Employers should ensure properly trained workers’ inspect the following vehicle systems to determine if they are working properly:

- Brakes: Brakes should provide even and balanced braking. Also check that brake fluid is at the proper level.

- Cooling System: Ensure a proper mixture of 50/50 antifreeze and water in the cooling system at the proper level.

- Electrical System: Check the ignition system and make sure that the battery is fully charged and that the connections are clean. Check that the alternator belt is in good condition with proper tension.

- Engine: Inspect all engine systems.

- Exhaust System: Check exhaust for leaks and that all clamps and hangers are snug.

- Tires: Check for proper tread depth and no signs of damage or uneven wear. Check for proper tire inflation.

- Oil: Check that oil is at proper level.

- Visibility Systems: Inspect all exterior lights, defrosters (windshield and rear window), and wipers. Install winter windshield wipers.

An emergency kit with the following items is recommended in vehicles:

- Cellphone or two-way radio

- Windshield ice scraper

- Snow brush

- Flashlight with extra batteries

- Shovel

- Tow chain

- Traction aids (bag of sand or cat litter)

- Emergency flares

- Jumper cables

- Snacks

- Water

- Road maps

- Blankets, change of clothes

Practice cold weather driving!

- During daylight, rehearse maneuver slowly on the ice or snow in an empty lot

- Steer into a skid

- Know what your brakes will do: stomp on antilock brakes, pump non-antilock brakes

- Stopping distances are longer on watercovered ice and ice

- Don’t idle for a long time with the windows up or in an enclosed space

Prevent crashes

- Drugs and alcohol never mix with driving

- Slow down and increase distances between cars

- Keep your eyes open for pedestrians walking in the road

- Avoid fatigue – Get plenty of rest before the trip, stop at least every three hours and rotate drivers if possible

Stranded in a vehicle

- If you are stranded in a vehicle, stay in the vehicle. Call for emergency assistance if needed, response time may be slow in severe winter weather conditions. Notify your supervisor of your situation. Do not leave the vehicle to search for assistance unless help is visible within 100 yards. You may become disoriented and get lost in blowing and drifting snow. Display a trouble sign by raising the hood. Turn on the vehicle’s engine for about 10 minutes each hour and run the heat to keep warm. Also, turn on the vehicle’s dome light when the vehicle is running as an additional signal. Beware of carbon monoxide poisoning. Keep the exhaust pipe clear of snow and open a downwind window slightly for ventilation.

- Watch for signs of frostbite and hypothermia. Do minor exercises to maintain good blood circulation in your body. Clap hands and move arms and legs occasionally. Try not to stay in one position for too long. Stay awake, you will be less vulnerable to cold-related health problems. Use blankets, newspapers, maps, and even the removable car mats for added insulation. Avoid overexertion since cold weather puts an added strain on the heart. Unaccustomed exercise such as shoveling snow or pushing a vehicle can bring on a heart attack or make other medical conditions worse.

Shoveling snow

- Shoveling snow can be a strenuous activity, particularly because cold weather can be tasking on the body. There is a potential for exhaustion, dehydration, back injuries or heart attacks. During snow removal, in addition to following the tips for avoiding cold stress, such as taking frequent breaks in warm areas, there are other precautions workers can take to avoid injuries. Workers should warm-up before the activity, scoop small amounts of snow at a time and where possible, push the snow instead of lifting it. The use of proper lifting technique is necessary to avoid back and other injuries when shoveling snow: keep the back straight, lift with the legs and do not turn or twist the body.

Using powered equipment like snow blowers

- It is important to make sure that powered equipment, such as snow blowers are properly grounded to protect workers from electric shocks or electrocutions. When performing maintenance or cleaning, make sure the equipment is properly guarded and is disconnected from power sources.

- Snow blowers commonly cause lacerations or amputations when operators attempt to clear jams with the equipment turned on. Never attempt to clear a jam by hand. First, turn the snow blower off and wait for all moving parts to stop, and then use a long stick to clear wet snow or debris from the machine. Keep your hands and feet away from moving parts. Refuel a snow blower prior to starting the machine; do not add fuel when the equipment is running or when the engine is hot.

Fall prevention

Preventing slips on snow and ice

To prevent slips, trips and falls, employers should clear snow and ice from walking surfaces and spread deicer, as quickly as possible after a winter storm. When walking on snow or ice is unavoidable workers should be trained to:

- Wear footwear that has good traction and insulation (e.g. insulated and water resistant boots or rubber over-shoes with good rubber treads)

- Take short steps and walk at a slower pace to react quickly to changes in traction

Preventing falls when removing snow from elevated surfaces

OSHA’s Hazard Alert and winter weather webpages provide guidance to employers on how to prevent serious injuries and fatalities. Employers should consider options to avoid working on roofs or elevated heights, plan ahead for safe snow removal and must:

- Provide required fall protection and training when working on the roof or elevated heights

- Ensure ladders are used safely (e.g. clearing snow and ice from surfaces)

- Use extreme caution when working near power lines

- Prevent harmful exposure to cold temperatures and physical exertion

Safety Tips for Workers

- Your employer should ensure that you know the symptoms of cold stress

- Monitor your physical condition and that of your coworkers

- Dress appropriately for the cold

- Stay dry in the cold because moisture or dampness, e.g. from sweating, can increase the rate of heat loss from the body

- Keep extra clothing (including underwear) handy in case you get wet and need to change

- Drink warm sweetened fluids (no alcohol)

- Use proper engineering controls, safe work practices and personal protective equipment (PPE) provided by your employer

Dressing Properly for the Cold

Dressing properly is extremely important to preventing cold stress. When cold environments or temperatures cannot be avoided, the following would help protect workers from cold stress:

- Wear at least three layers of loose fitting clothing. Layering provides better insulation.

- An inner layer of wool, silk or synthetic (polypropylene) to keep moisture away from the body. Thermal wear, wool, silk or polypropylene, inner layers of clothing that will hold more body heat than cotton.

- A middle layer of wool or synthetic to provide insulation even when wet.

- An outer wind and rain protection layer that allows some ventilation to prevent overheating.

- Tight clothing reduces blood circulation. Warm blood needs to be circulated to the extremities. Insulated coat/jacket (water resistant if necessary)

- Knit mask to cover face and mouth (if needed)

- Hat that will cover your ears as well. A hat will help keep your whole body warmer. Hats reduce the amount of body heat that escapes from your head.

- Insulated gloves (water resistant if necessary), to protect the hands

- Insulated and waterproof boots to protect the feet

Know your winter weather terms

Blizzard Warning: Issued for sustained or gusty winds of 35 mph or more, and falling or blowing snow creating visibilities at or below 1/4 mile; these conditions should persist for at least three hours.

Wind Chill Advisory: Issued when wind chill temperatures are expected to be a significant inconvenience to life with prolonged exposure, and, if caution is not exercised, could lead to hazardous exposure.

Wind Chill Warning: Issued when wind chill temperatures are expected to be hazardous to life within several minutes of exposure.

Winter Storm Warning: Issued when hazardous winter weather in the form of heavy snow, blizzard conditions, heavy freezing rain or heavy sleet is imminent or occurring. Winter Storm Warnings are usually issued 12 to 24 hours before the event is expected to begin.

Winter Storm Watch: Alerts the public to the possibility of a blizzard, heavy snow, heavy freezing rain or heavy sleet. Winter Storm watches are usually issued 12 to 48 hours before the beginning of a winter storm.

Winter Weather Advisories: Issued for accumulations of snow, freezing rain, freezing drizzle and sleet which will cause significant inconveniences and, if caution is not exercised, could lead to life threatening situations.

(From: National Oceanic and Atmospheric Administration (NOAA))

In a blow to safety, the U.S. Department of Transportation (DOT) repealed a 2015 Federal Railroad Administration (FRA) rule that required railroads to implement electronically controlled pneumatic (ECP) braking technology on trains hauling hazardous flammable contents.

“Clearly the railroad industry’s overwhelming influence over the Trump administration is paying off in repealing the ECP brake rule,” said SMART TD National Legislative Director John Risch. “ECP brakes are the safest, most advanced braking systems in the world and without some government requirement we will continue to use our current, outdated 150-year-old braking technology for the foreseeable future.”

The ECP brakes mandate was part of the 2015 rulemaking on DOT-117 tank cars. The rule stated that trains meeting the definition of a high-hazard flammable unit train (HHFUT) with at least one tank care with Packing Group I materials must be operated with ECP brakes by Jan. 1, 2021, or face reduced maximum speeds. All other HHFUT’s were required to have the system installed after 2023. DOT defines HHFUT as a single train with 70 or more tank cars loaded with Class 3 flammable liquids.

The Association of American Railroads has been lobbying for repeal of the rulemaking since its 2015 inception.

In Nov. 2017, Risch made comments to the Pipeline and Hazardous Materials Safety Administration (PHMSA) in support of ECP braking technology. Click here to read those comments.

A backhoe operator and a track supervisor were killed, and 39 people were injured when Amtrak train 89, traveling on the Northeast Corridor from Philadelphia to Washington on track three, struck a backhoe at about 7:50 a.m. The train engineer saw equipment and people working on and near track three and initiated emergency braking that slowed the train from 106 mph to approximately 99 mph at the time of impact.

The NTSB also determined allowing a passenger train to travel at maximum authorized speed on unprotected track where workers were present, the absence of shunting devices, the foreman’s failure to conduct a job briefing at the start of the shift, all coupled with the numerous inconsistent views of safety and safety management throughout Amtrak, led to the accident.

“Amtrak’s safety culture is failing, and is primed to fail again, until and unless Amtrak changes the way it practices safety management,” said NTSB Chairman Robert L. Sumwalt. “Investigators found a labor-management relationship so adversarial that safety programs became contentious at the bargaining table, with the unions ultimately refusing to participate.”

The NTSB also noted the Federal Railroad Administration’s failure to require redundant signal protection, such as shunting, for maintenance-of-way work crews contributed to this accident.

Post-accident toxicology determined that the backhoe operator tested positive for cocaine, and the track supervisor had tested positive for codeine and morphine. The locomotive engineer tested positive for marijuana. The NTSB determined that while drug use was not a factor in this accident, it was symptomatic of a weak safety culture at Amtrak.

As a result of this investigation, the NTSB issued 14 safety recommendations including nine to Amtrak.

The NTSB also made two safety recommendations to the Federal Railroad Administration, and three safety recommendations were issued to the Brotherhood of Maintenance of Way Employees Division, American Railway and Airway Supervisors Association, Brotherhood of Locomotive Engineers and Trainmen and Brotherhood of Railroad Signalmen.

The abstract of the NTSB’s final report, that includes the findings, probable cause and safety recommendations is available online here. The final report will be publicly released in the next several days.

The webcast of the board meeting for this investigation is available for 90 days here.