OSHA and National Oceanic and Atmospheric Administration (NOAA) are working together on a public education effort aimed at improving the way people prepare for and respond to severe weather. Here is some information provided by OSHA to help businesses and their workers prepare for winter weather, and to provide information about hazards that workers may face during and after winter storms.

Winter preparedness

Outdoor work requires proper preparation, especially in severe winter weather conditions. Although OSHA does not have a specific standard that covers working in cold environments, employers have a responsibility to provide workers with employment and a place of employment which are free from recognized hazards, including winter weather related hazards, which are causing or are likely to cause death or serious physical harm to them (Section 5(a)(1) of the Occupational Safety and Health Act of 1970). Employers should, therefore, train workers on the hazards of the job and safety measures to use, such as engineering controls and safe work practices, that will protect workers’ safety and health.

Employers should train workers

At a minimum, employers should train workers on:

- Cold Stress:

- How to recognize the symptoms of cold stress, prevent cold stress injuries and illnesses

- The importance of self-monitoring and monitoring coworkers for symptoms

- First aid and how to call for additional medical assistance in an emergency

- How to select proper clothing for cold, wet and windy conditions

- Other winter weather related hazards that workers may be exposed to, for example, slippery roads and surfaces, windy conditions and downed power lines

- How to recognize these hazards

- How workers will be protected: engineering controls, safe work practices and proper selection of equipment, including personal protective equipment

Employers should implement safe work practices

Safe work practices that employers can implement to protect workers from injuries, illnesses and fatalities include:

- Providing workers with the proper tools and equipment to do their jobs

- Developing work plans that identify potential hazards and the safety measures that will be used to protect workers

- Scheduling maintenance and repair jobs for warmer months

- Scheduling jobs that expose workers to the cold weather in the warmer part of the day

- Avoiding exposure to extremely cold temperatures when possible

- Limiting the amount of time spent outdoors on extremely cold days

- Using relief workers to assign extra workers for long, demanding jobs

- Providing warm areas for use during break periods

- Providing warm liquids (no alcohol) to workers

- Monitoring workers who are at risk of cold stress

- Monitoring the weather conditions during a winter storm, having a reliable means of communicating with workers and being able to stop work or evacuate when necessary

- Acclimatizing new workers and those returning after time away from work by gradually increasing their workload, and allowing more frequent breaks in warm areas, as they build up a tolerance for working in the cold environment

- Having a means of communicating with workers, especially in remote areas

- Knowing how the community warns the public about severe weather: outdoor sirens, radio and television

- The National Oceanic and Atmospheric Administration (NOAA) provides multiple ways to stay informed about winter storms. If you are notified of a winter storm watch, advisory or warning, follow instructions from your local authorities: NOAA Weather Radio

Employers should consider protective clothing that provides warmth

Employers must provide personal protective equipment (PPE), for example, fall protection, when required by OSHA standards to protect workers’ safety and health. However, in limited cases specified in the standard (29 CFR 1910.132), there are exceptions to the requirement for employers to provide PPE to workers. For instance, there is no OSHA requirement for employers to provide workers with ordinary clothing, skin creams or other items, used solely for protection from weather, such as winter coats, jackets, gloves, parkas, rubber boots, hats, raincoats, ordinary sunglasses and sunscreen (29 CFR 1910.132(h)(4)). Regardless of this, many employers provide their workers with winter weather gear such as winter coats/jackets and gloves.

Learn more about PPE requirements: Personal Protective Equipment (OSHA Safety and Health Topics Page).

Wind Chill temperature

National Weather Service (NWS) Wind Chill Calculator: With this tool, one may input the air temperature and wind speed, and it will calculate the wind chill temperature.

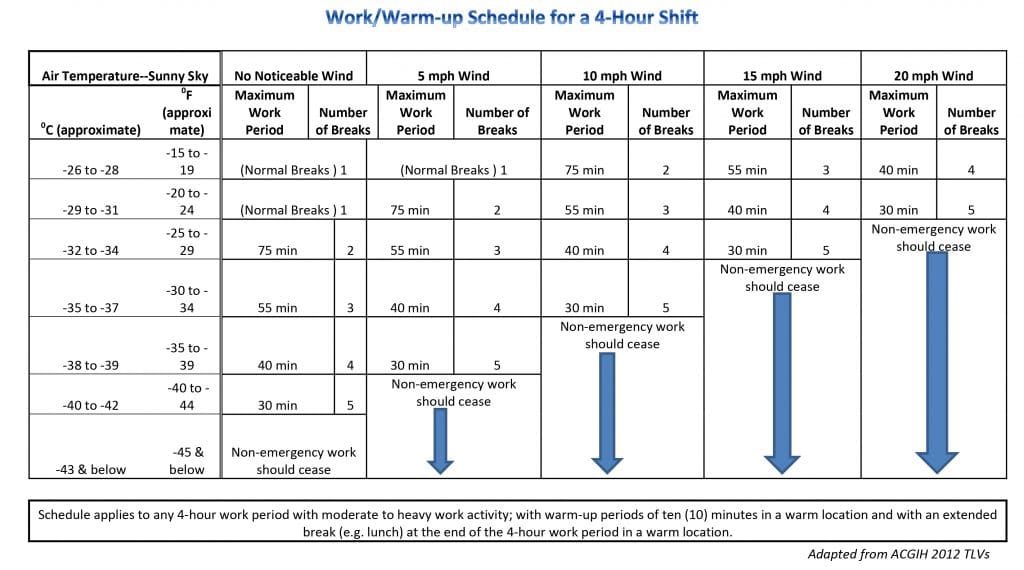

The American Conference of Governmental Industrial Hygienists (ACGIH) developed the following Work/Warm-up Schedule for a 4-hour shift takes both air temperature and wind speed into account, to provide recommendations on scheduling work breaks and ceasing non-emergency work.

Cold Stress

Cold Stress can be prevented

The National Oceanic and Atmospheric Administration (NOAA) Weather Radio is a nationwide network of radio stations broadcasting continuous weather information from the nearest NWS office. It will give information when wind chill conditions reach critical thresholds. A Wind Chill Warning is issued when wind chill temperatures are life threatening. A Wind Chill Advisory is issued when wind chill temperatures are potentially hazardous.

Who is affected by environmental cold?

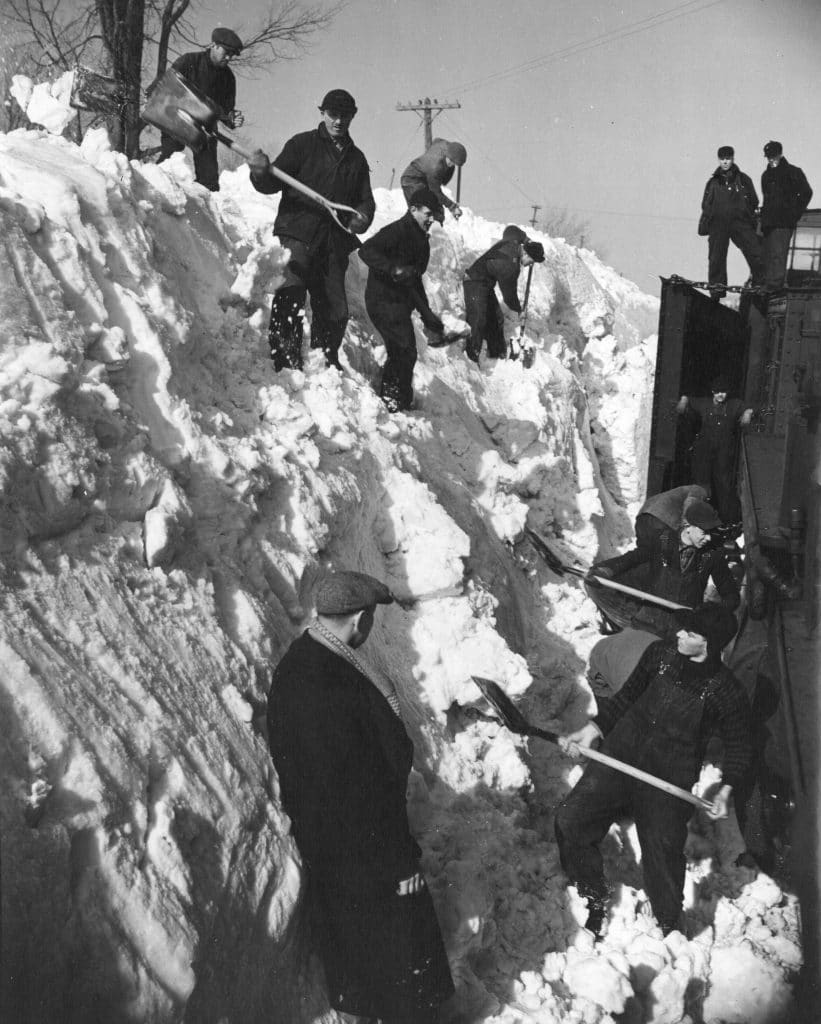

Environmental cold can affect any worker exposed to cold air temperatures and puts workers at risk of cold stress. As wind speed increases, it causes the cold air temperature to feel even colder, increasing the risk of cold stress to exposed workers, especially those working outdoors, such as recreational workers, snow cleanup crews, construction workers, police officers and firefighters. Other workers who may be affected by exposure to environmental cold conditions include those in transit, baggage handlers, water transportation, landscaping services and support activities for oil and gas operations.

Risk factors for cold stress include:

- Wetness/dampness, dressing improperly and exhaustion

- Predisposing health conditions such as hypertension, hypothyroidism and diabetes

- Poor physical conditioning

What is cold stress?

What constitutes cold stress and its effects can vary across different areas of the country. In regions that are not used to winter weather, near freezing temperatures are considered factors for “cold stress.” Increased wind speed also causes heat to leave the body more rapidly (wind chill effect). Wetness or dampness, even from body sweat, also facilitates heat loss from the body. Cold stress occurs by driving down the skin temperature, and eventually the internal body temperature. When the body is unable to warm itself, serious cold-related illnesses and injuries may occur, and permanent tissue damage and death may result. Types of cold stress include: trench foot, frostbite and hypothermia.

For more information, see OSHA’s Cold Stress Safety and Health Guide.

How can cold stress be prevented?

Although OSHA does not have a specific standard that covers working in cold environments, under the Occupational Safety and Health Act (OSH Act) of 1970, employers have a duty to protect workers from recognized hazards, including cold stress hazards, that are causing or likely to cause death or serious physical harm in the workplace.

- Employers should train workers. Training should include:

- How to recognize the environmental and workplace conditions that can lead to cold stress.

- The symptoms of cold stress, how to prevent cold stress and what to do to help those who are affected.

- How to select proper clothing for cold, wet and windy conditions.

- Employers should:

- Monitor workers physical condition.

- Schedule frequent short breaks in warm, dry areas to allow the body to warm up.

- Schedule work during the warmest part of the day.

- Use the buddy system (work in pairs).

- Provide warm, sweet beverages. Avoid drinks with alcohol.

- Provide engineering controls such as radiant heaters.

Types of Cold Stress

Immersion/Trench Foot

Trench foot is a non-freezing injury of the feet caused by prolonged exposure to wet and cold conditions. It can occur in temperatures as high as 60°F if feet are constantly wet. Injury occurs because wet feet lose heat 25 times faster than dry feet.

What are they symptoms of trench foot?

Reddening skin, tingling, pain, swelling, leg cramps, numbness and blisters.

First Aid

- Call 911 immediately in an emergency; otherwise seek medical assistance as soon as possible.

- Remove wet shoes/boots and wet socks.

- Dry the feet and avoid working on them.

- Keep affected feet elevated and avoid walking. Get medical attention.

Frostbite

Frostbite is caused by the freezing of the skin and tissues. Frostbite can cause permanent damage to the body, and in severe cases can lead to amputation. The risk of frostbite is increased in people with reduced blood circulation and among people who are not dressed properly for extremely cold temperatures.

What are the symptoms of frostbite?

Reddened skin develops gray/white patches in the fingers, toes, nose or ear lobes; tingling, aching, a loss of feeling, firm/hard blisters may occur in the affected areas.

First Aid

- Follow the recommendations described below for hypothermia.

- Protect the frostbitten area, e.g., by wrapping loosely in a dry cloth and protect the area from contact until medical help arrives.

- DO NOT rub the affected area, because rubbing causes damage to the skin and tissue.

- Do not apply snow or water. Do not break blisters.

- DO NOT try to re-warm the frostbitten area before getting medical help, for example, do not use heating pads or place in warm water. If a frostbitten area is rewarmed and gets frozen again, more tissue damage will occur. It is safer for the frostbitten area to be rewarmed by medical professionals.

- Give warm sweetened drinks if alert (no alcohol).

Hypothermia

Hypothermia occurs when the normal body temperature (98.6°F) drops to less than 95°F. Exposure to cold temperatures causes the body to lose heat faster than it can be produced. Prolonged exposure to cold will eventually use up the body’s stored energy. The result is hypothermia, or abnormally low body temperature. Hypothermia is most likely at very cold temperatures, but it can occur even at cool temperatures (above 40°F) if a person becomes chilled from rain, sweat or immersion in cold water.

What are the symptoms of hypothermia?

An important mild symptom of hypothermia is uncontrollable shivering, which should not be ignored. Although shivering indicates that the body is losing heat, it also helps the body to rewarm itself. Moderate to severe symptoms of hypothermia are loss of coordination, confusion, slurred speech, heart rate/breathing slow, unconsciousness and possibly death. Body temperature that is too low affects the brain, making the victim unable to think clearly or move well. This makes hypothermia particularly dangerous because a person may not know what is happening and won’t be able to do anything about it.

First Aid

- Call 911 immediately in an emergency:

- Move the worker to a warm, dry area.

- Remove any wet clothing and replace with dry clothing. Wrap the entire body (including the head and neck) in layers of blankets; and with a vapor barrier (e.g. tarp, garbage bag) Do not cover the face.

- If medical help is more than 30 minutes away:

- Give warm sweetened drinks if alert (no alcohol), to help increase the body temperature. Never try to give a drink to an unconscious person.

- Place warm bottles or hot packs in armpits, sides of chest and groin. Call 911 for additional rewarming instructions.

Basic Life Support (when necessary)

Co-workers trained in cardiopulmonary resuscitation (CPR) may help a person suffering from hypothermia that has no pulse or is not breathing:

- Call 911 for emergency medical assistance immediately.

- Treat the worker as per instructions for hypothermia, but be very careful and do not try to give an unconscious person fluids.

- Check him/her for signs of breathing and for a pulse. Check for 60 seconds.

- If after 60 seconds the affected worker is not breathing and does not have a pulse, trained workers may start rescue breaths for 3 minutes.

- Recheck for breathing and pulse, check for 60 seconds.

- If the worker is still not breathing and has no pulse, continue rescue breathing.

- Only start chest compressions per the direction of the 911 operator or emergency medical services*

- Reassess patient’s physical status periodically.

*Chest compression are recommended only if the patient will not receive medical care within three hours.

Winter driving

Although employers cannot control roadway conditions, they can promote safe driving

Employers should set and enforce driver safety policies. Employers should also implement an effective maintenance program for all vehicles and mechanized equipment that workers are required to operate. Crashes can be avoided. Learn more at: Motor Vehicle Safety (OSHA Safety and Health Topic’s Page).

Employers should ensure properly trained workers’ inspect the following vehicle systems to determine if they are working properly:

- Brakes: Brakes should provide even and balanced braking. Also check that brake fluid is at the proper level.

- Cooling System: Ensure a proper mixture of 50/50 antifreeze and water in the cooling system at the proper level.

- Electrical System: Check the ignition system and make sure that the battery is fully charged and that the connections are clean. Check that the alternator belt is in good condition with proper tension.

- Engine: Inspect all engine systems.

- Exhaust System: Check exhaust for leaks and that all clamps and hangers are snug.

- Tires: Check for proper tread depth and no signs of damage or uneven wear. Check for proper tire inflation.

- Oil: Check that oil is at proper level.

- Visibility Systems: Inspect all exterior lights, defrosters (windshield and rear window), and wipers. Install winter windshield wipers.

An emergency kit with the following items is recommended in vehicles:

- Cellphone or two-way radio

- Windshield ice scraper

- Snow brush

- Flashlight with extra batteries

- Shovel

- Tow chain

- Traction aids (bag of sand or cat litter)

- Emergency flares

- Jumper cables

- Snacks

- Water

- Road maps

- Blankets, change of clothes

Practice cold weather driving!

- During daylight, rehearse maneuver slowly on the ice or snow in an empty lot

- Steer into a skid

- Know what your brakes will do: stomp on antilock brakes, pump non-antilock brakes

- Stopping distances are longer on watercovered ice and ice

- Don’t idle for a long time with the windows up or in an enclosed space

Prevent crashes

- Drugs and alcohol never mix with driving

- Slow down and increase distances between cars

- Keep your eyes open for pedestrians walking in the road

- Avoid fatigue – Get plenty of rest before the trip, stop at least every three hours and rotate drivers if possible

Stranded in a vehicle

- If you are stranded in a vehicle, stay in the vehicle. Call for emergency assistance if needed, response time may be slow in severe winter weather conditions. Notify your supervisor of your situation. Do not leave the vehicle to search for assistance unless help is visible within 100 yards. You may become disoriented and get lost in blowing and drifting snow. Display a trouble sign by raising the hood. Turn on the vehicle’s engine for about 10 minutes each hour and run the heat to keep warm. Also, turn on the vehicle’s dome light when the vehicle is running as an additional signal. Beware of carbon monoxide poisoning. Keep the exhaust pipe clear of snow and open a downwind window slightly for ventilation.

- Watch for signs of frostbite and hypothermia. Do minor exercises to maintain good blood circulation in your body. Clap hands and move arms and legs occasionally. Try not to stay in one position for too long. Stay awake, you will be less vulnerable to cold-related health problems. Use blankets, newspapers, maps, and even the removable car mats for added insulation. Avoid overexertion since cold weather puts an added strain on the heart. Unaccustomed exercise such as shoveling snow or pushing a vehicle can bring on a heart attack or make other medical conditions worse.

Shoveling snow

- Shoveling snow can be a strenuous activity, particularly because cold weather can be tasking on the body. There is a potential for exhaustion, dehydration, back injuries or heart attacks. During snow removal, in addition to following the tips for avoiding cold stress, such as taking frequent breaks in warm areas, there are other precautions workers can take to avoid injuries. Workers should warm-up before the activity, scoop small amounts of snow at a time and where possible, push the snow instead of lifting it. The use of proper lifting technique is necessary to avoid back and other injuries when shoveling snow: keep the back straight, lift with the legs and do not turn or twist the body.

Using powered equipment like snow blowers

- It is important to make sure that powered equipment, such as snow blowers are properly grounded to protect workers from electric shocks or electrocutions. When performing maintenance or cleaning, make sure the equipment is properly guarded and is disconnected from power sources.

- Snow blowers commonly cause lacerations or amputations when operators attempt to clear jams with the equipment turned on. Never attempt to clear a jam by hand. First, turn the snow blower off and wait for all moving parts to stop, and then use a long stick to clear wet snow or debris from the machine. Keep your hands and feet away from moving parts. Refuel a snow blower prior to starting the machine; do not add fuel when the equipment is running or when the engine is hot.

Fall prevention

Preventing slips on snow and ice

To prevent slips, trips and falls, employers should clear snow and ice from walking surfaces and spread deicer, as quickly as possible after a winter storm. When walking on snow or ice is unavoidable workers should be trained to:

- Wear footwear that has good traction and insulation (e.g. insulated and water resistant boots or rubber over-shoes with good rubber treads)

- Take short steps and walk at a slower pace to react quickly to changes in traction

Preventing falls when removing snow from elevated surfaces

OSHA’s Hazard Alert and winter weather webpages provide guidance to employers on how to prevent serious injuries and fatalities. Employers should consider options to avoid working on roofs or elevated heights, plan ahead for safe snow removal and must:

- Provide required fall protection and training when working on the roof or elevated heights

- Ensure ladders are used safely (e.g. clearing snow and ice from surfaces)

- Use extreme caution when working near power lines

- Prevent harmful exposure to cold temperatures and physical exertion

Safety Tips for Workers

- Your employer should ensure that you know the symptoms of cold stress

- Monitor your physical condition and that of your coworkers

- Dress appropriately for the cold

- Stay dry in the cold because moisture or dampness, e.g. from sweating, can increase the rate of heat loss from the body

- Keep extra clothing (including underwear) handy in case you get wet and need to change

- Drink warm sweetened fluids (no alcohol)

- Use proper engineering controls, safe work practices and personal protective equipment (PPE) provided by your employer

Dressing Properly for the Cold

Dressing properly is extremely important to preventing cold stress. When cold environments or temperatures cannot be avoided, the following would help protect workers from cold stress:

- Wear at least three layers of loose fitting clothing. Layering provides better insulation.

- An inner layer of wool, silk or synthetic (polypropylene) to keep moisture away from the body. Thermal wear, wool, silk or polypropylene, inner layers of clothing that will hold more body heat than cotton.

- A middle layer of wool or synthetic to provide insulation even when wet.

- An outer wind and rain protection layer that allows some ventilation to prevent overheating.

- Tight clothing reduces blood circulation. Warm blood needs to be circulated to the extremities. Insulated coat/jacket (water resistant if necessary)

- Knit mask to cover face and mouth (if needed)

- Hat that will cover your ears as well. A hat will help keep your whole body warmer. Hats reduce the amount of body heat that escapes from your head.

- Insulated gloves (water resistant if necessary), to protect the hands

- Insulated and waterproof boots to protect the feet

Know your winter weather terms

Blizzard Warning: Issued for sustained or gusty winds of 35 mph or more, and falling or blowing snow creating visibilities at or below 1/4 mile; these conditions should persist for at least three hours.

Wind Chill Advisory: Issued when wind chill temperatures are expected to be a significant inconvenience to life with prolonged exposure, and, if caution is not exercised, could lead to hazardous exposure.

Wind Chill Warning: Issued when wind chill temperatures are expected to be hazardous to life within several minutes of exposure.

Winter Storm Warning: Issued when hazardous winter weather in the form of heavy snow, blizzard conditions, heavy freezing rain or heavy sleet is imminent or occurring. Winter Storm Warnings are usually issued 12 to 24 hours before the event is expected to begin.

Winter Storm Watch: Alerts the public to the possibility of a blizzard, heavy snow, heavy freezing rain or heavy sleet. Winter Storm watches are usually issued 12 to 48 hours before the beginning of a winter storm.

Winter Weather Advisories: Issued for accumulations of snow, freezing rain, freezing drizzle and sleet which will cause significant inconveniences and, if caution is not exercised, could lead to life threatening situations.

(From: National Oceanic and Atmospheric Administration (NOAA))

The Rail Workers Hazardous Materials Training Program is pleased to announce the following HazMat/Chemical Emergency Response Training Programs. This training addresses OSHA and DOT required training in addition to procedures, different levels of response and worker protection in a hazardous materials emergency or release, weapons of mass destruction awareness and the incident command system. The training also provides completion of the OSHA 10-Hour General Industry Outreach requirements. The programs are delivered using interactive classroom instruction, small group activities, hands-on drills and a simulated hazmat response in full safety gear.

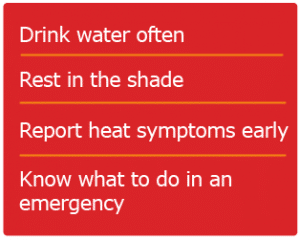

The Rail Workers Hazardous Materials Training Program is pleased to announce the following HazMat/Chemical Emergency Response Training Programs. This training addresses OSHA and DOT required training in addition to procedures, different levels of response and worker protection in a hazardous materials emergency or release, weapons of mass destruction awareness and the incident command system. The training also provides completion of the OSHA 10-Hour General Industry Outreach requirements. The programs are delivered using interactive classroom instruction, small group activities, hands-on drills and a simulated hazmat response in full safety gear. OSHA’s Heat Illness Prevention campaign, launched in 2011, educates employers and workers on the dangers of working in the heat. Through training sessions, outreach events, informational sessions, publications, social media messaging and media appearances, millions of workers and employers have learned how to protect workers from heat. OSHA’s safety message comes down to three key words: Water. Rest. Shade.

OSHA’s Heat Illness Prevention campaign, launched in 2011, educates employers and workers on the dangers of working in the heat. Through training sessions, outreach events, informational sessions, publications, social media messaging and media appearances, millions of workers and employers have learned how to protect workers from heat. OSHA’s safety message comes down to three key words: Water. Rest. Shade. DENVER – An investigation by the U.S. Department of Labor’s

DENVER – An investigation by the U.S. Department of Labor’s  Anyone working in a cold environment may be at risk of cold stress. Some workers may be required to work outdoors in cold environments and for extended periods, for example, snow cleanup crews, sanitation workers, police officers and emergency response and recovery personnel, like firefighters, and emergency medical technicians. Cold stress can be encountered in these types of work environment. The following frequently asked questions will help workers understand what cold stress is, how it may affect their health and safety, and how it can be prevented.

Anyone working in a cold environment may be at risk of cold stress. Some workers may be required to work outdoors in cold environments and for extended periods, for example, snow cleanup crews, sanitation workers, police officers and emergency response and recovery personnel, like firefighters, and emergency medical technicians. Cold stress can be encountered in these types of work environment. The following frequently asked questions will help workers understand what cold stress is, how it may affect their health and safety, and how it can be prevented. The body normally cools itself by sweating. During hot weather, especially with high humidity, sweating isn’t enough. Body temperature can rise to dangerous levels if you don’t drink enough water and rest in the shade. You can suffer from heat exhaustion or heat stroke.

The body normally cools itself by sweating. During hot weather, especially with high humidity, sweating isn’t enough. Body temperature can rise to dangerous levels if you don’t drink enough water and rest in the shade. You can suffer from heat exhaustion or heat stroke.

WASHINGTON – The U.S. Department of Transportation’s Federal Motor Carrier Safety Administration (FMCSA) announced the publication in the Federal Register of a Final Rule to help further safeguard commercial truck and bus drivers from being compelled to violate federal safety regulations. The Rule provides FMCSA with the authority to take enforcement action not only against motor carriers, but also against shippers, receivers, and transportation intermediaries.

WASHINGTON – The U.S. Department of Transportation’s Federal Motor Carrier Safety Administration (FMCSA) announced the publication in the Federal Register of a Final Rule to help further safeguard commercial truck and bus drivers from being compelled to violate federal safety regulations. The Rule provides FMCSA with the authority to take enforcement action not only against motor carriers, but also against shippers, receivers, and transportation intermediaries.