The Federal Railroad Administration June 3 issued a safety advisory on the importance railroad safety procedures to ensure the safety of the traveling public and railroad employees when highway-rail grade crossing warning systems and wayside signal systems are temporarily removed from service for purposes of testing, inspection, maintenance, or repair.

The Federal Railroad Administration June 3 issued a safety advisory on the importance railroad safety procedures to ensure the safety of the traveling public and railroad employees when highway-rail grade crossing warning systems and wayside signal systems are temporarily removed from service for purposes of testing, inspection, maintenance, or repair.

Safety Advisory 2013-04 also notes that “under certain circumstances, particularly where human error is involved, the fail-safe features [of warning systems] can be deactivated or circumvented, creating the potential for an accident. FRA has found that serious highway-rail grade crossing accidents and false proceed signal failures have occurred due to human error.”

According to the FRA, the most effective practices to prevent this include requiring railroad employees to obtain proper authority from the train dispatcher or other appropriate personnel responsible for the movement of trains through the territory before disabling a warning or signaling system, and a requirement that all disabled systems be properly inspected and tested to ensure they operate as designed before being restored to service.

The list of recommended actions include:

1. Each railroad responsible for the proper operation of a highway-rail grade crossing warning system or wayside signal system review and evaluate its specific railroadwide instructions for the proper method for temporary removal of these systems from service. These instructions should address the following items:

- a. The manner in which the deactivation is authorized.

- b. The personnel designated to authorize deactivation.

- c. The protocols for notifying appropriate persons, especially personnel responsible for the movement of trains, that a grade crossing warning system or wayside signal system has been temporarily removed from service.

- d. The appropriate methods of providing for the safety of train movements while the grade crossing warning system or wayside signal system is temporarily removed from service.

- e. The requirements necessary to perform an inspection and operational test of the pertinent system components before restoring the grade crossing warning system or wayside signal system to service.

- f. The protocols for documenting and notifying appropriate persons that the grade crossing warning system or wayside signal system has been properly tested and restored to service.

2. Each railroad provide regular periodic training to all affected employees to ensure their understanding of instructions for the proper procedures for the temporary removal from service of grade crossing warning or wayside signal systems, including the proper use of jumper wires.

Highway-rail grade crossing warning devices and wayside train signals are among the most important safety systems in the railroad industry for preventing train collisions and highway-rail grade crossing accidents. Despite the high degree of reliability of these systems, failures occasionally do occur.

FRA previously made related recommendations to railroads regarding the importance of clear safety procedures to ensure the safety of highway-rail grade crossing warning systems and wayside signal systems in Safety Advisory 2002–01.

To read the complete advisory and background, which was published June 3 in the Federal Register, click here.

WASHINGTON – The Federal Railroad Administration (FRA) May 3 issued an industry-wide safety advisory to warn about safety hazards associated with flat switching operations on railroads. Since 2009, six railroad employees sustained fatal injuries placing themselves between unsecured rolling equipment during switching operations, including one employee who was killed last year.

WASHINGTON – The Federal Railroad Administration (FRA) May 3 issued an industry-wide safety advisory to warn about safety hazards associated with flat switching operations on railroads. Since 2009, six railroad employees sustained fatal injuries placing themselves between unsecured rolling equipment during switching operations, including one employee who was killed last year. The Federal Railroad Administration has issued a new report on the status of fatigue among railroad industry employees.

The Federal Railroad Administration has issued a new report on the status of fatigue among railroad industry employees.

One of the strongest studies validating the need for two-person crews and intensive training for conductors has come from the Federal Railroad Administration.

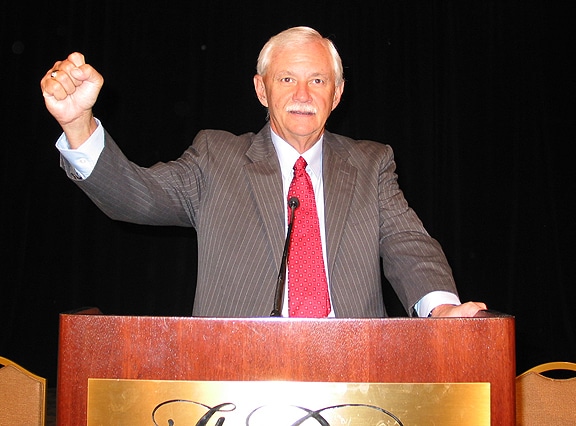

One of the strongest studies validating the need for two-person crews and intensive training for conductors has come from the Federal Railroad Administration. UTU International President Mike Futhey

UTU International President Mike Futhey