The National Academy of Sciences (NAS) released a long-awaited study Sept. 17 examining issues associated with the increasing lengths of freight trains.

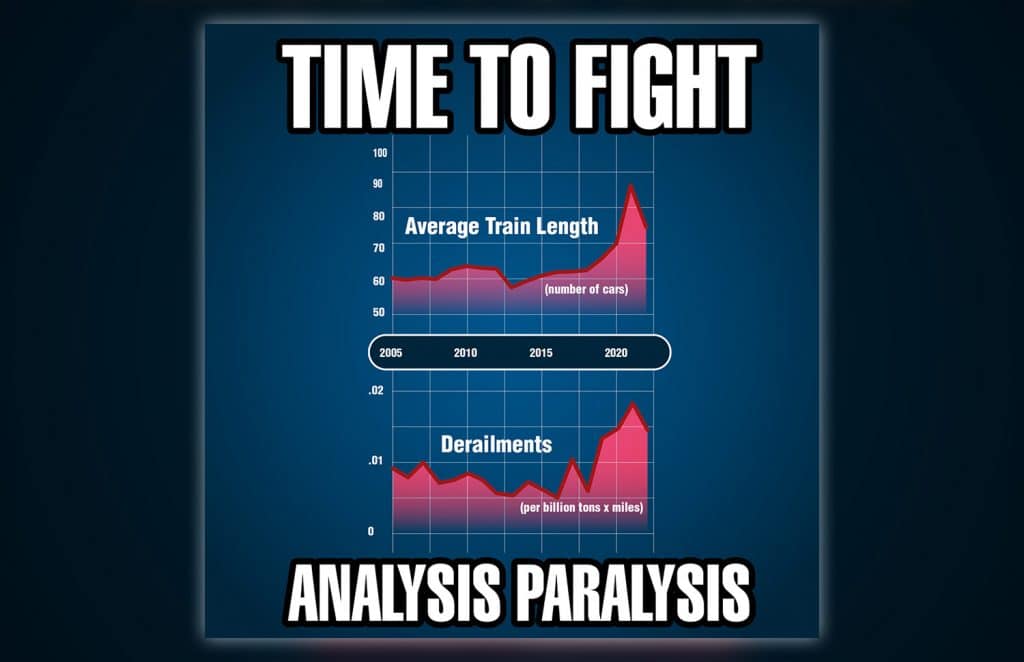

Jared Cassity, SMART-TD’s alternate national legislative director, sums up their findings: “The fact that we are seeing a high rate of derailments despite fewer trains underscores the critical risks associated with longer trains. This puts not only our members but also the public in danger.”

This is understood, but that no one is ready to act is a troubling trend.

Fewer trains, same number of derailments

SMART Transportation Division, the largest railroad union in the United States, has also observed that longer trains pose significant risks. We are disappointed that the study doesn’t recommend specific action to address the problem they identified. The safety challenges presented by the lengthening of trains doesn’t require further study. Decisive action is needed.

The study confirms what we have long been saying: The longer the trains get, the greater the risks, and these risks are not being mitigated effectively.

Railroads are holding back data on long trains

Unfortunately, the thoroughness of the NAS report was undermined by a notable lack of data from rail carriers and the Association of American Railroads (AAR). This gap in data collection is disappointing, preventable and entirely predictable.

“It is incredibly frustrating to see the railroad companies and their representatives deliberately withhold crucial data that could have led to a more comprehensive and actionable report,” Cassity stated. “The failure to provide complete information is a clear attempt by these companies to avoid accountability and continue their practices unchecked.”

Meanwhile, it’s the same story from the railroads, as their head mouthpiece repeated the same talking points they habitually roll out.

“Safety is at the center of every decision on the railroad, and train length is no different,” AAR President and CEO Ian Jefferies said. “As operations continue to evolve, railroads are pulling on three key levers — technology, training and infrastructure — to further enhance safety and reliability.”

SMART-TD presses for new train length laws and regulations

We had hoped that the NAS investigation would bridge the gap between information gathering and actionable solutions. Instead, no conclusions about what an appropriate maximum train length should be were drawn from the research.

Meanwhile, AAR labeled the 7,500-foot length — approximately a mile and a half — used by the study as a measuring point as “arbitrary” when defining what constitutes a “long” train.

“The study followed a congressionally defined threshold without uniform agreement on its appropriateness,” they said.

As experts on the ground, our members can shed some light. Longer trains benefit railroad carriers by increasing their operational efficiency and profits. This comes at the expense of quality of life for railroad workers, growing hazards for the public and poorer service for the companies waiting for their shipments. Longer trains contribute to more catastrophic derailments, increased response times for first responders at blocked crossings, and more significant logistical challenges overall.

SMART-TD calls for immediate and decisive action to address the issues associated with long trains. We are engaging with legislators and regulatory bodies who are entrusted with railroad oversight. They have a duty to address these hazards, as we have an obligation to preserve the well-being of railroad workers and the public who are affected by the trains we operate every day.

WASHINGTON (Jan. 11, 2018) — The National Transportation Safety Board (NTSB) issued four railroad related safety recommendations in concert with the agency’s publication of two railroad accident briefs Thursday, Jan. 11.

WASHINGTON (Jan. 11, 2018) — The National Transportation Safety Board (NTSB) issued four railroad related safety recommendations in concert with the agency’s publication of two railroad accident briefs Thursday, Jan. 11. On May 8, 2015, the Pipeline and Hazardous Materials Safety Administration, in coordination with the Federal Railroad Administration (FRA), published a final rule entitled, “Hazardous Materials: Enhanced Tank Car Standards and Operational Controls for High-Hazard Flammable Trains,” which adopted requirements designed to reduce the consequences and, in some instances, reduce the probability of accidents involving trains transporting large quantities of Class 3 flammable liquids.

On May 8, 2015, the Pipeline and Hazardous Materials Safety Administration, in coordination with the Federal Railroad Administration (FRA), published a final rule entitled, “Hazardous Materials: Enhanced Tank Car Standards and Operational Controls for High-Hazard Flammable Trains,” which adopted requirements designed to reduce the consequences and, in some instances, reduce the probability of accidents involving trains transporting large quantities of Class 3 flammable liquids. WASHINGTON – A congressional proposal that would see much heavier trucks on the nation’s highways will cost taxpayers billions of dollars in damaged roads and bridges while further straining already depleted federal coffers, one of the nation’s top transportation representatives said Wednesday.

WASHINGTON – A congressional proposal that would see much heavier trucks on the nation’s highways will cost taxpayers billions of dollars in damaged roads and bridges while further straining already depleted federal coffers, one of the nation’s top transportation representatives said Wednesday.

U.S. freight railroad traffic continued its ongoing slump last week, with U.S. railroads reporting a total 562,884 carloads and intermodal units for the week ending Aug. 8, down 0.9 percent compared with the same week last year, according to the

U.S. freight railroad traffic continued its ongoing slump last week, with U.S. railroads reporting a total 562,884 carloads and intermodal units for the week ending Aug. 8, down 0.9 percent compared with the same week last year, according to the