When the public school that housed SMART Sheet Metal Local No. 4’s training center abruptly closed last spring, the program — and the union — were at a bit of a loss. In the end, the experience proved to be a blessing in disguise.

Through a partnership with the local school district, Local No. 4’s training center was housed inside a public adult training center that was closed due to a school district consolidation. Local No. 4 had to move all equipment and materials out of the building quickly, regroup and figure out a next step.

The union hall, housed in a 7,500-square-foot building, wasn’t large enough to take on the training center as a whole; however, there was space for classes. To accommodate the situation and to maintain apprenticeship progression in the program, the curriculum was front-loaded to give students all their coursework in hopes they would find a building in time to allow apprentices to complete their fabrication shop requirements for the year. During that time, students completed training in reading blueprints, plans and specifications and the 30-hour Occupational Safety and Health Administration (OSHA) course, said John Williams, business manager for Local No. 4.

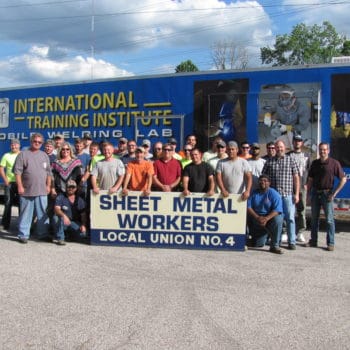

In August 2016, Local No. 4 found a new, 12,500-square-foot building — one that could not only house the training program, but the union hall as well. The International Training Institute (ITI), the education arm of the unionized sheet metal, air conditioning and welding industry, sent out the mobile welding trailer, so apprentices could complete their welding classes and any certifications in the interim.

“The idea is to keep training moving forward no matter the circumstances, so the ITI was happy to help keep these apprentices current on their skills,” said Mike Harris, ITI program director. “The mobile welding trailer was created for situations much like this one, and it’s serving its purpose well until Local No. 4’s welding lab is complete.”

The new warehouse-style building allowed for large pieces of equipment to be moved in immediately, so apprentices could get started on their fabrication shop curriculum and renovations could begin simultaneously. Welding and computer labs as well as plans for CNC machines and other technology are in the works. It’s a blank slate, Williams said.

“The great thing about having a new facility is we can upgrade our training to the future of our industry,” Williams added. “At the other building, we had our hands tied. Now, we have a new facility with plenty of space in the union hall area to have classes while we’re renovating everything.”

There is also space to offer continuing education classes to journeypersons and, once renovations are complete, bring in potential apprentices for tours as part of recruitment efforts. One of the goals is to use the new center and union hall to teach apprentices and get them experience to help supplement the workforce when members retire.

“We can build it the way we want it, to suit our needs. There are so many possibilities,” Williams said. “The goal is to turn out more than you retire. That’s not happening. We’re looking over the next five to 10 years, and the eligibility for retirement is going to exceed the number of apprentices. This new building will help us attract new apprentices and continue to educate our current workforce.”

Local 4 members are excited and have a reason to be. Once the renovation is complete, the training center will far exceed previous accommodations, Williams said.

Related News

- Kansas funds passenger rail expansion

- SMART’s General President Defends Our Brother

- Maryland Passes Monumental Transit Safety Bill

- Brother Wirth Crowned Champion in 168-Pound Masters Division Victory

- Chairman Pauli Announces Retirement, SMART-TD celebrates his career

- SMART statement on Supreme Court’s decision regarding Kilmar Armando Abrego Garcia’s return to the United States

- SMART-TD Stands With Brother Kilmar Abrego Garcia

- New Mexico Local 1687 sets new precedent with Red Apple Transit

- Tentative Agreement Reached With TransitAmerica Services (TASI)

- SMART issues Monday, April 7, statement on Kilmar Armando Abrego Garcia’s ongoing case